Metallic Expansion Joints

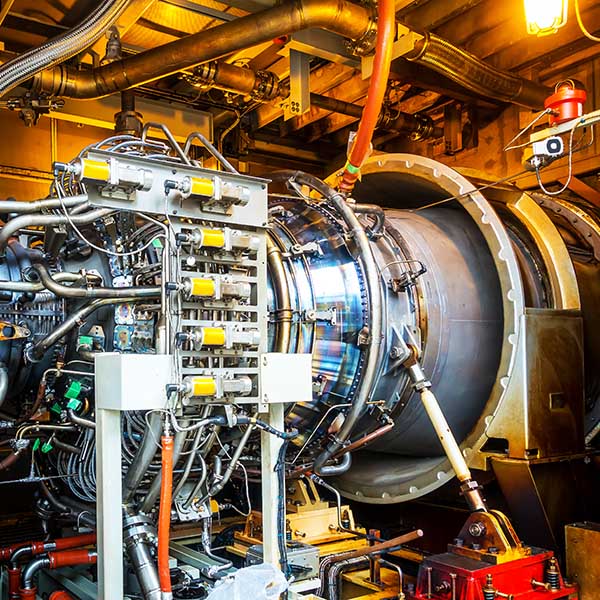

Vibrant Power designs and develops a variety of expansion joints used in industrial environments due to their intense vibration and thermal growth conditions.

Industrial environments are some of the harshest environments you can encounter, subject to intense heat, pressure, vibration, and their combined effect on equipment components. Vibrant Power has been a major player in the development of metallic expansion joints to address the dynamics of such environments. With this in mind, our metallic expansion joints are available in many types of (and not limited to) of stainless steel, nickel-chromium alloys (Inconel, Hastelloy), nickel-copper alloy (Monel), high nickel alloys, corrosion-resistant Duplex stainless steel, and Titanium.

Metallic Expansion Joint Stamps and Certifications:

- ISO 9001

- ASME U Stamp – B31.1, B31.3 and ASME Section VIII

- European Pressure Equipment Directive PED (CE)

- Canadian CRN

- Expansion Joint Manufacturers Association (EJMA)

Our engineers are ready to assist you in choosing an Expansion Joint design that is optimum, as well as economical. Vibrant Power has designed and supplied all types of Expansion Joints from small exhaust connectors to huge turbine crossovers, many with a variety of external hardware and/or refractory linings.

Some examples of the types of Expansion Joints available are:

- Single

- Universal, Universal Tied

- Hinged

- Gimbal

- Pressure balanced

Additional Capabilities for Metallic Expansion Joints:

- Tube Welding/Forming

- Hydroforming, Roll Forming,

Punch Forming - TIG, MIG & Plasma Welding

- Finite Element Analysis (FEA)

- Multi-ply Bellows

- EJMA Standards Calculations

- High Volume Manufacturing

We custom-design and produce metallic expansion joints for steam and condensate lines, vibration control, high temperature/high pressure, corrosive, and motion/displacement applications. Our customers have trusted our expertise and knowledge to solve both common and rare needs, always using our problem-solving approach to find effective solutions.

Vibrant Power actively works with customers in these industries:

Oil & Gas

Pulp & Paper

Water & Sewage Treatment Plants

Chemical Plants

Power Plants

Petrochemical

Mining

Cement

Steelmaking

Shipbuilding

Utilities

Our commitment to quality control and customer satisfaction includes our ISO 9001:2015 certification and adherence to ASME, CE and EJMA Standards. Vibrant Power has always been dedicated to ensuring our components and assemblies meet the most rigorous standards., ensuring our customers will be pleased with the end result.

For Canadian customers, any expansion joints designed over 15 PSIG will be supplied with a Canadian Registration Number (CRN).

We can customize any metallic expansion joint to ensure these components meet your exact specifications. Contact Vibrant today to discuss a specific application or performance needs.

The team at Vibrant Power is ready to answer any questions you have about this or any of our motion and vibration solutions.