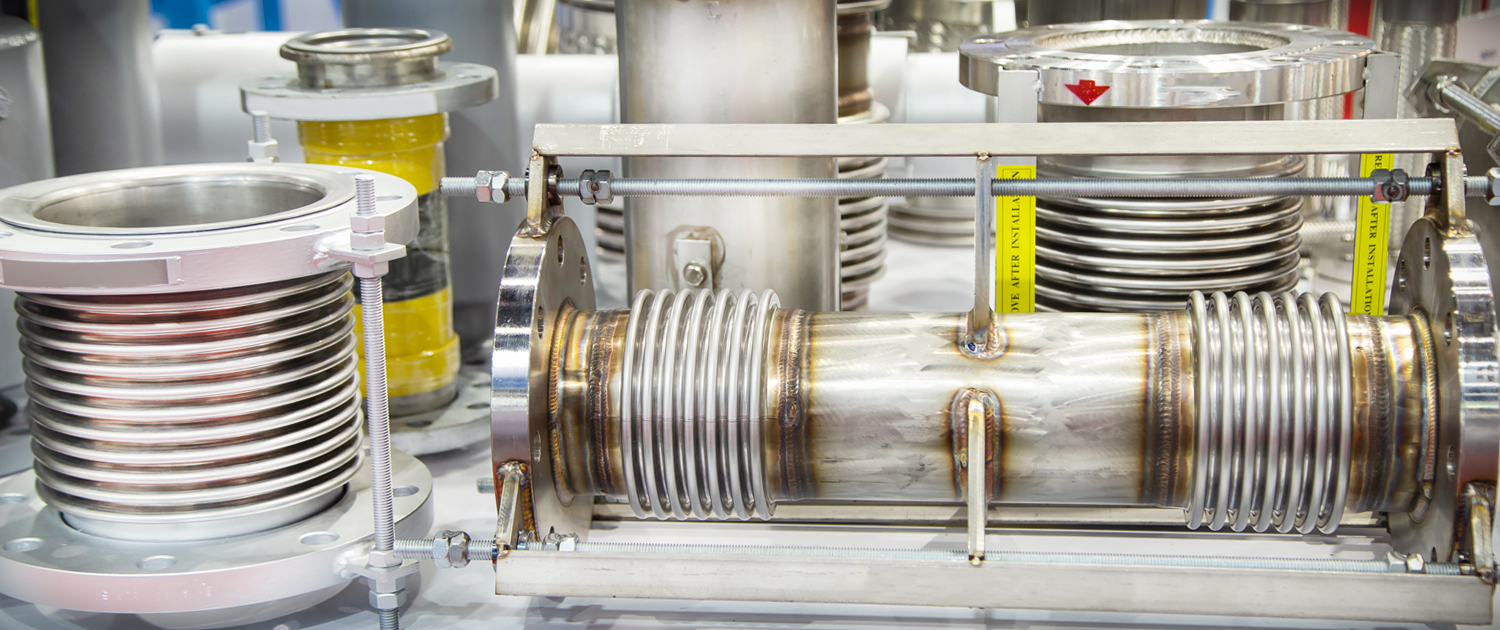

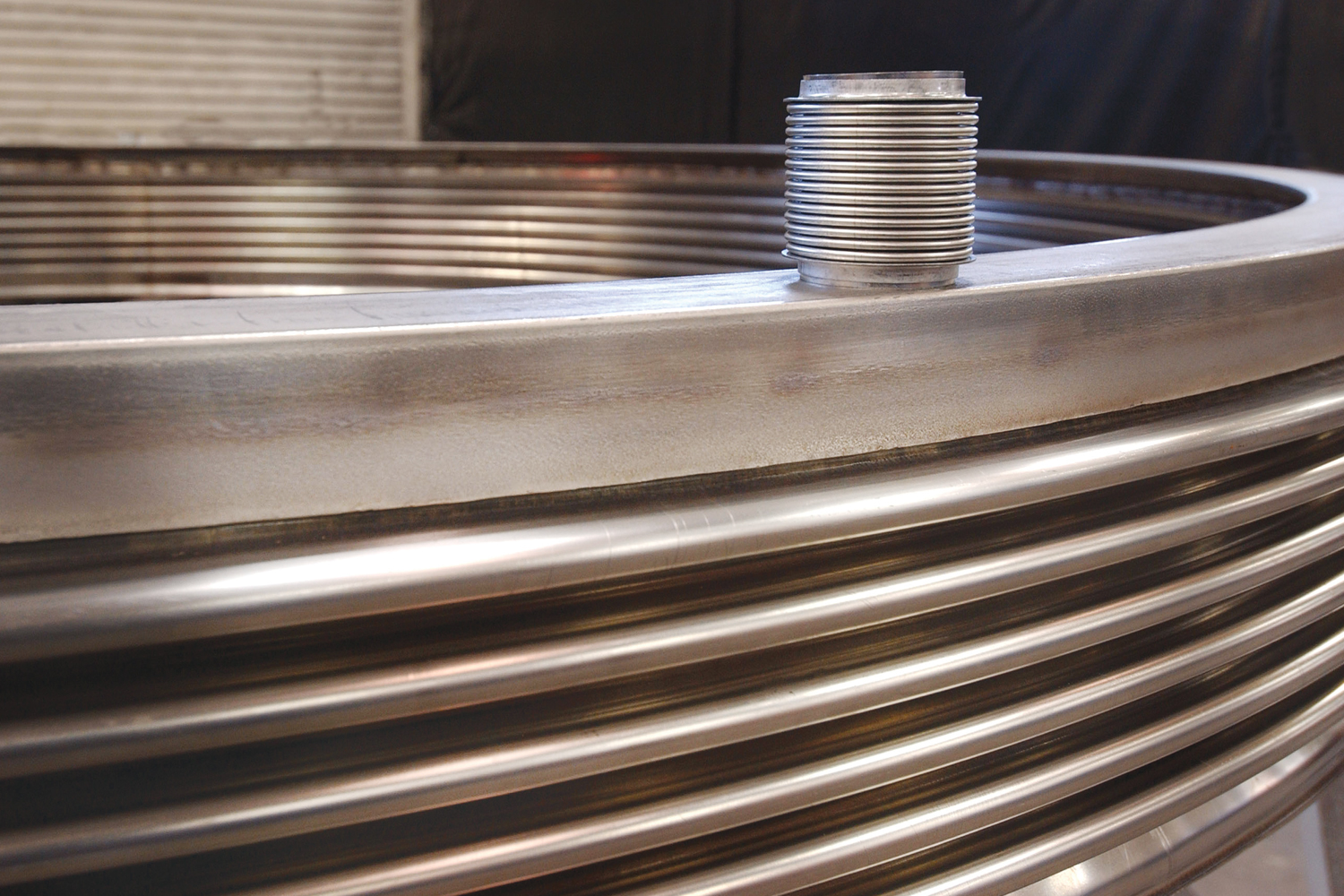

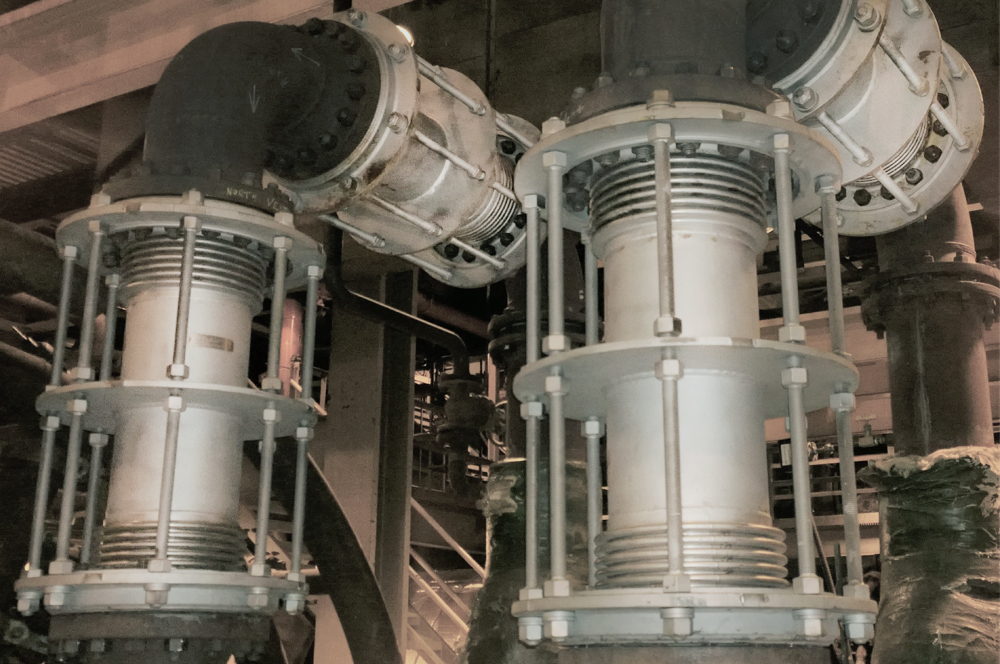

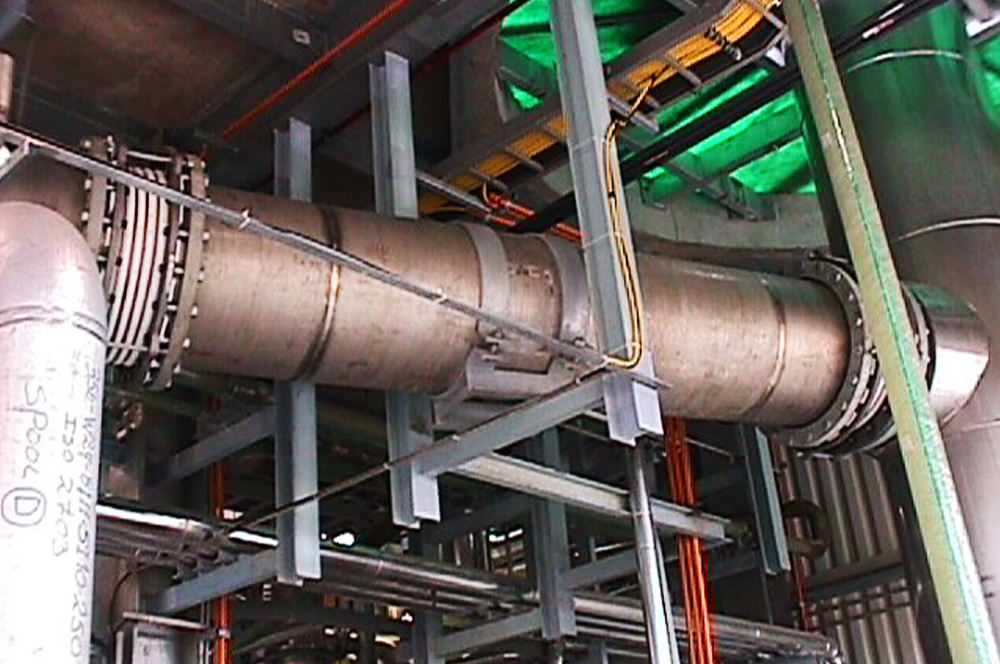

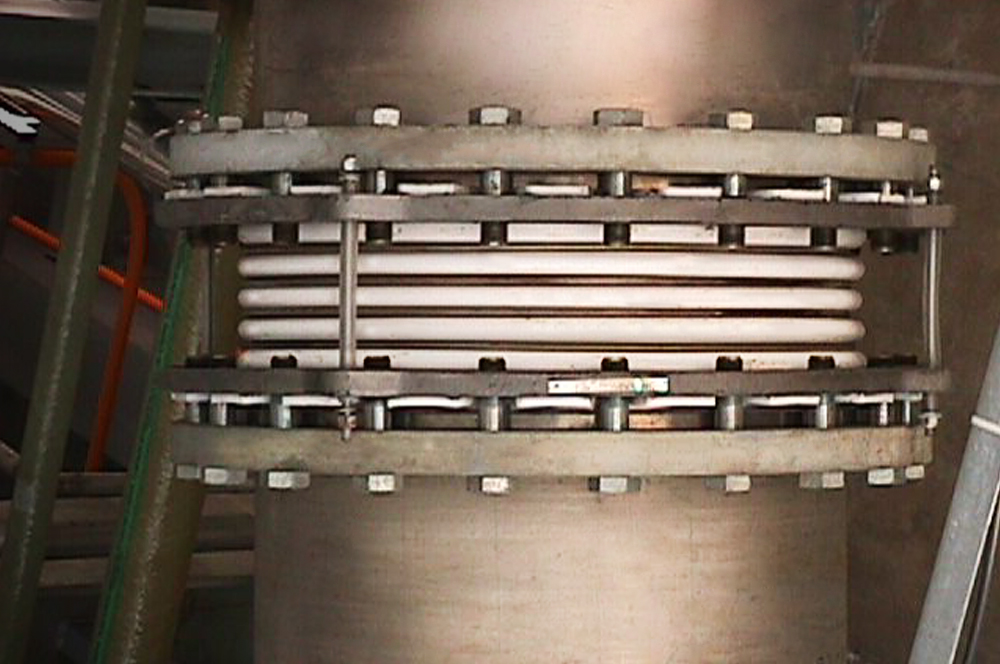

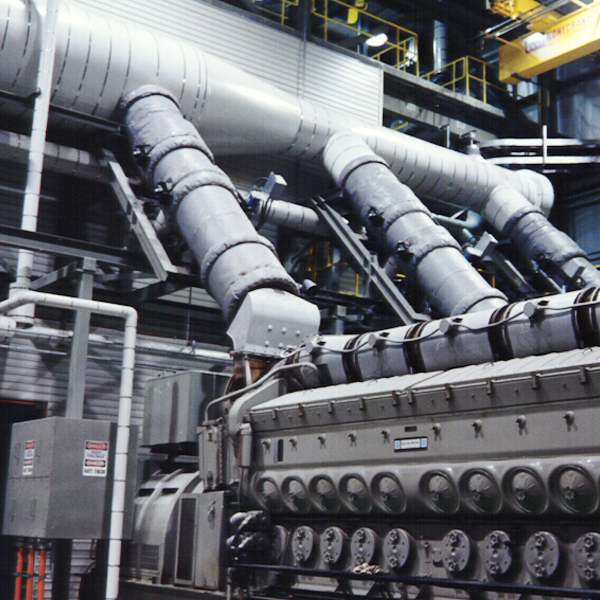

Industrial Expansion Joints

Vibrant Power designs and supplies a variety of expansion joints for a diverse range of uses and applications, allowing customers to mitigate thermal expansion, absorb vibrational forces, and handle motion/deflection that can create significant challenges for the reliable operation of piping, ducting and mechanical systems.

When designing an Expansion Joint into any system, it is very important to know the operating conditions in every area where an Expansion Joint will be installed. Our expert design team is very experienced in developing solutions for the most difficult applications and we can offer a wide array of expansion joint options to suit virtually any scenario.