Custom Manufacturing Capabilities

Vibrant Power provides customers access to a wide variety of manufacturing capabilities, allowing us to offer customized solutions to virtually any project presented to us.

The following list provides a snapshot of the more popular services and capabilities we offer, but we can do much more:

- Laser Cutting (including 3D Tube Laser Cutting)

- Plasma, Water Jet and Wire EDM cutting

- CNC Machining and Milling (up to 5 axes)

- Investment & Die Casting (Steel, Stainless Steel, Aluminum, Zinc Alloy, etc.)

- Hot and Cold Forging (Steel, Stainless Steel, Aluminum)

- Punching, Stamping & Deep Draw Metal Forming

- Hydro Forming

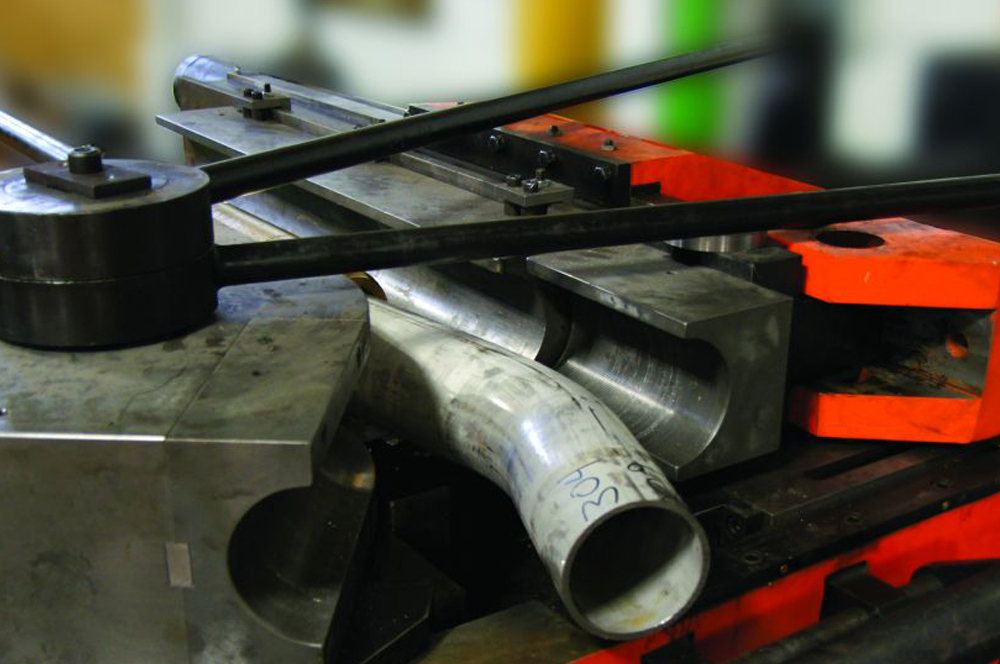

- Tube and Pipe Bending, 0.25” up to 5.00” O.D. (Mandrel & Compression)

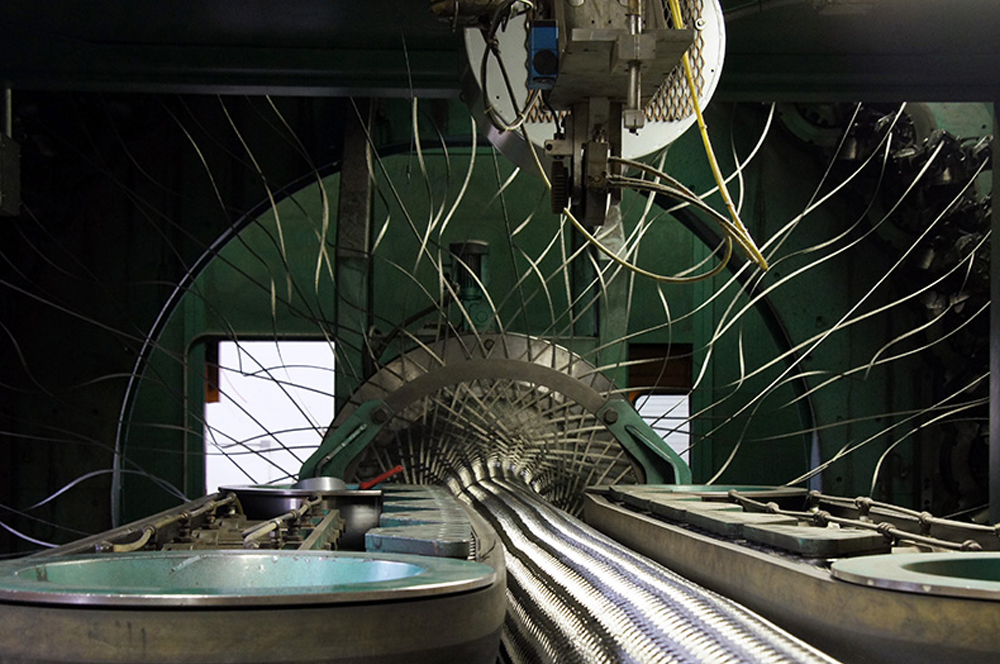

- Extrusions (Steel, Stainless Steel, Aluminum, Plastic, Rubber)

- Plastic Injection Moulding

- MIG and TIG welding (Steel, Stainless Steel, Aluminum, Titanium and other Exotic alloys)

- Metal Polishing, Anodizing, PVD Coating, Powder Coating and Wet Painting

- Chrome Plating, Zinc Plating, Passivation and Electropolishing

- Sandblasting

- Laser Engraving

- Hardcoat Insulation

- Surface Treatment from case hardening to tumble finishing

- 3D Printing / Rapid Prototyping

- Solidworks CAD capabilities, including stress analysis and flow simulation

- Custom Packaging Design and Manufacturing