Industrial Applications

Since 1985, Vibrant Power has provided solutions to customers on more than 100 different industrial sectors. Below, we offer some examples of typical applications for our products.

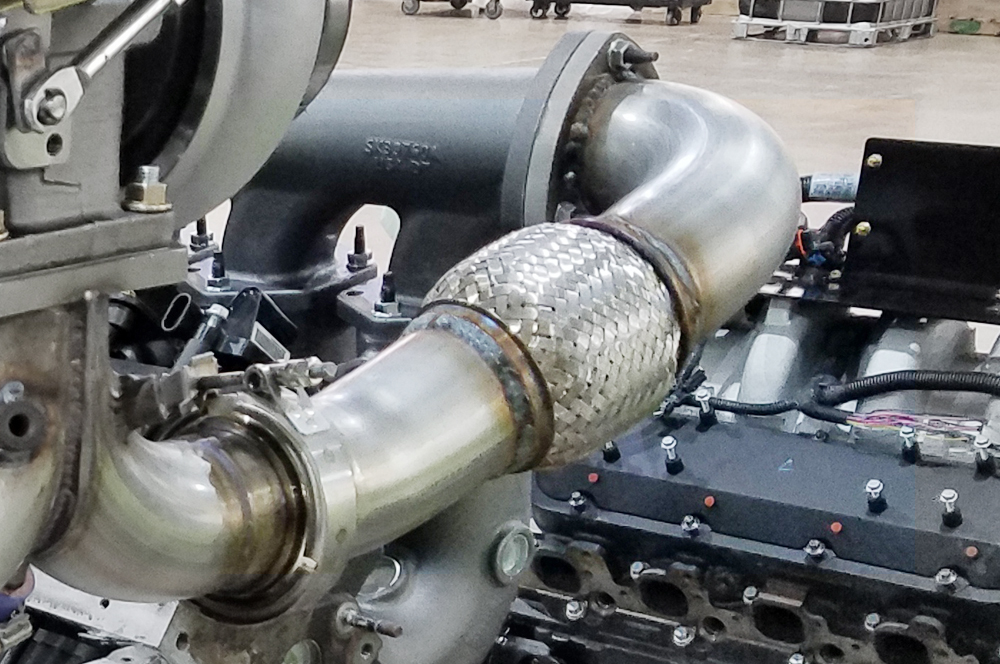

This photo represents a fairly typical application for a Vibrant Power Flexible Exhaust Coupling, welded into an exhaust pipe assembly designed for a Standby Generator exhaust system.

Vibrant can supply the components, like the Flexible Coupling, the V-Band Flange Assembly and the bent tubing or we can supply the entire exhaust assembly.

Vibrant silicone hoses are designed primarily for water, coolant and air service, but can also support oil and fuel service with the introduction of specialty internal liners that protect the hose from premature degradation. They are used in any number of applications and industries, including Automotive, Bus and Truck engines, generators, off-road vehicles, construction equipment and more.

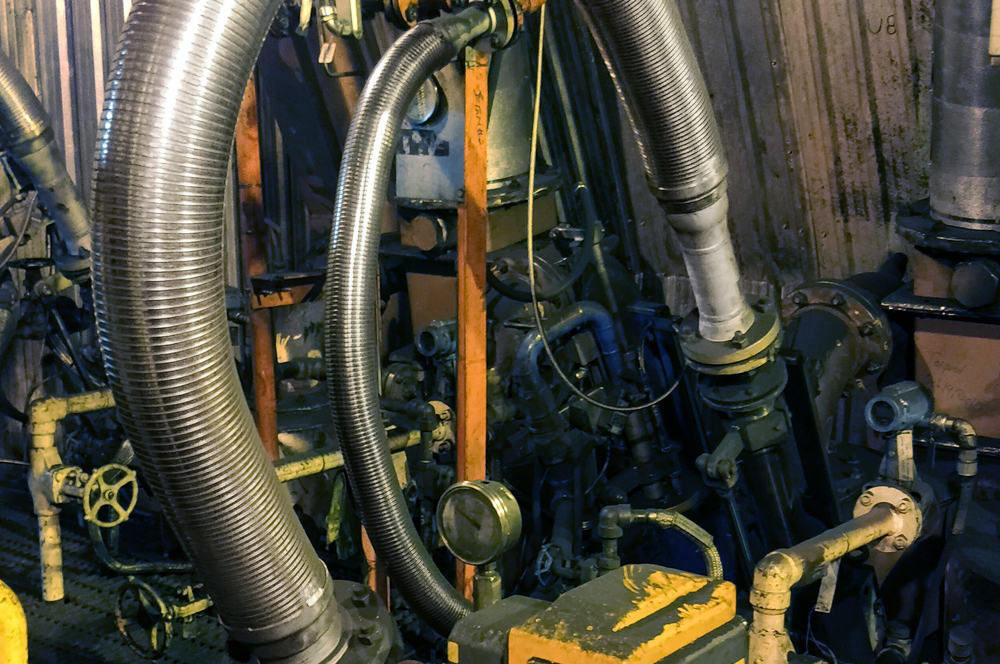

These “Transfer” or “Lance” hoses are designed to convey the movement of gas and liquids such as Water, Natural Gas, Chlorine and Oxygen, to name just a few.

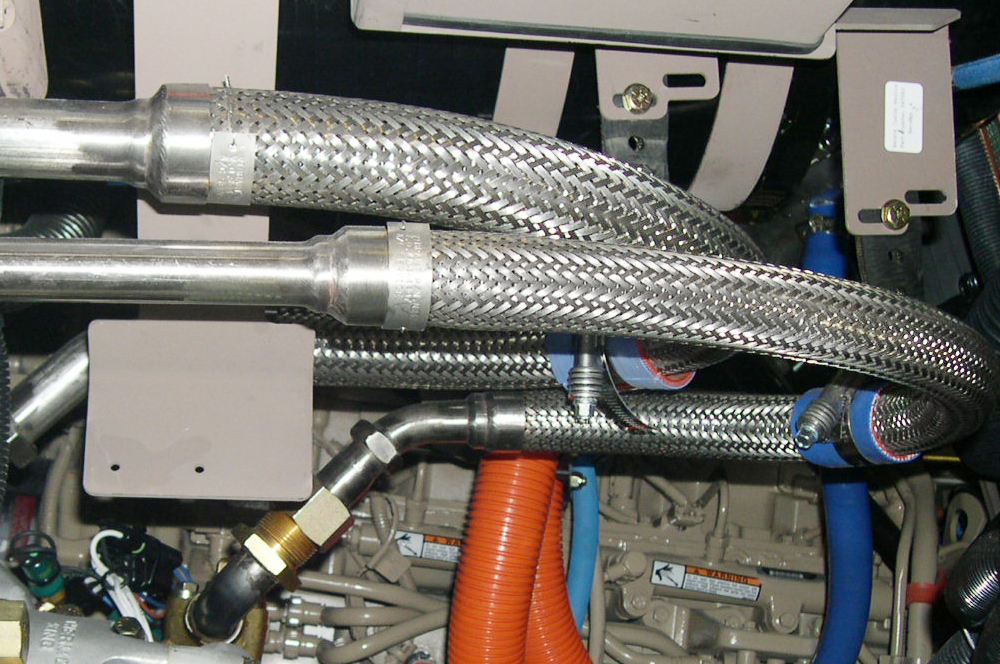

Non-permeable suction and discharge stainless steel braided air conditioning hoses for the bus and truck industries

Thermal blankets work to maintain and contain high engine exhaust temperatures. Thermal blanket covering of exhaust tubes and components control radiant heat in an engine bay and provide a cooler environment for wiring and rubber hoses, thereby prolonging their life expectancy.

Fabric Expansion Joints are designed to handle large movements in a short space with no size restrictions. They are commonly used in Cement Plants, Flue Gas Desulfurization Systems, Power and Recovery Boilers, Power Generation, and Pulp and Paper Plants.

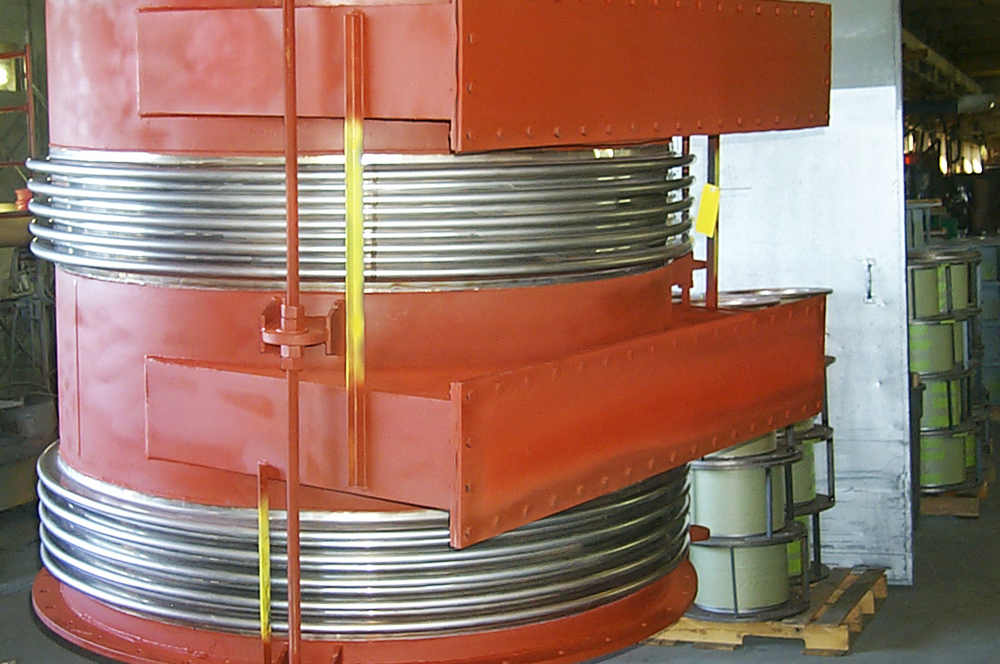

The internals of this Universal Tied Expansion Joint are designed to move the dust into the traps and then facilitate cleaning during a maintenance outage. This ensures the convolutions do not get filled with dust and continue to take the movements they were designed for. Universal Tied Expansion Joints are designed to absorb lateral movement and eliminate any thrust forces from the piping system.

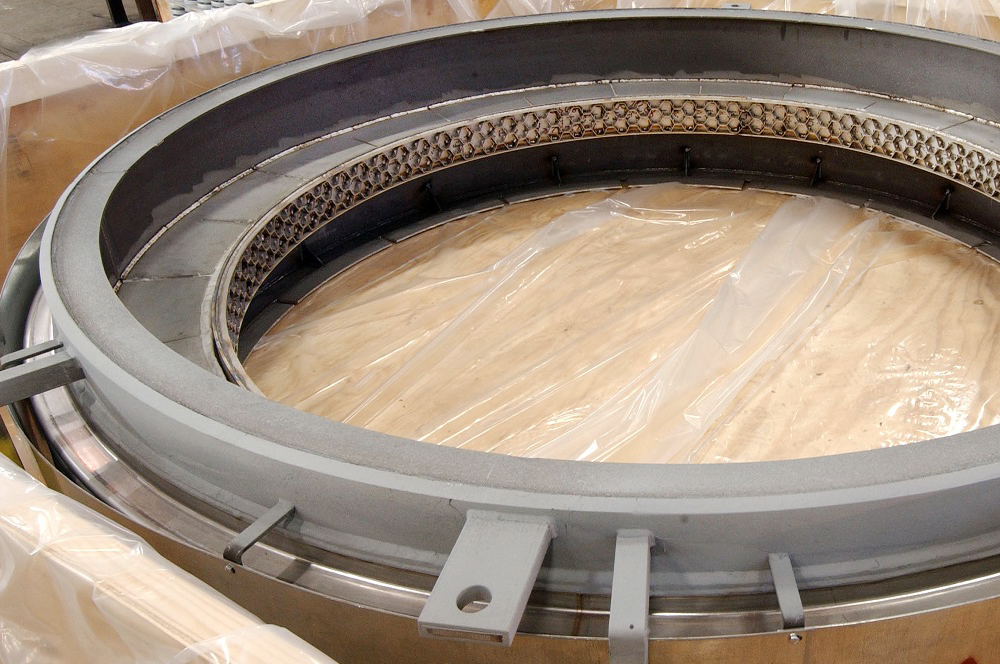

Refractory Lined Expansion Joints are typically used for very hot applications where the heat must be contained within the piping system. Applications include Gas Turbines, Catalytic Cracking Units, Thermal Oxidation Plants, and Quench Towers, to name a few.