Fabric Expansion Joints

Vibrant Power offers fabric expansion joints that provide both insulation and protection against abrasion while absorbing vibration more efficiently.

The advantages and benefits of fabric expansion joints vary by the application, environment, and other factors related to an industrial process. Vibrant Power’s experience covers a range of applications to include fly ash processes, industrial and commercial kilns, ducting, flue gases, and corrosive materials, among many others.

Fabric expansion joints offer superior flexibility and will handle large thermal movements, in a relatively short space. They are excellent for vibration isolation and also help reduce mechanical noise transmission. Fabric Expansion Joints are available in various materials and designs with no size restrictions. Expansion Joints can be supplied with appropriate metal work (such as angles, baffles, and retaining bars) for ease of installation at site.

Vibrant Power designs and manufactures fabric expansion joints for these industries:

Cement

Pulp & Paper

Pollution Control

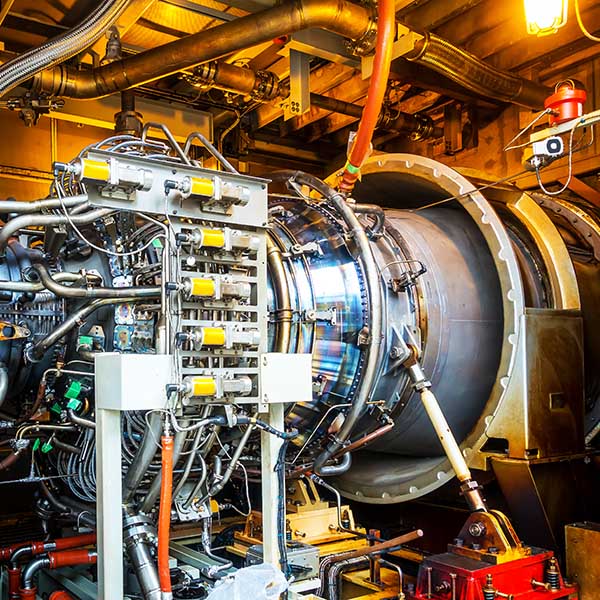

Power Plants

Utilities

Water & Sewage Treatment Plants

Oil & Gas

Petrochemical

Chemical Plants

Steelmaking

The use of fabric expansion joints as a non-metallic solution works well in ducting systems—allowing increased movement and the need for fewer expansion joints. We work with some of the top names in the production of elastomers to ensure the selection of premium materials best suited for a specific application of the fabric expansion joints.

We can customize fabric expansion joints to ensure these components meet your exact specifications. Contact Vibrant today to discuss a specific application or performance needs.

The team at Vibrant Power is ready to answer any questions you have about this or any of our motion and vibration solutions.